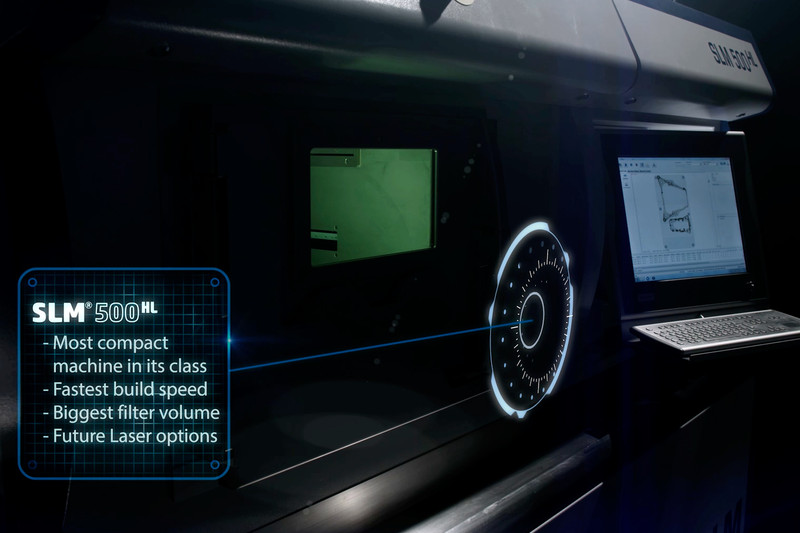

Create complex and large components efficiently

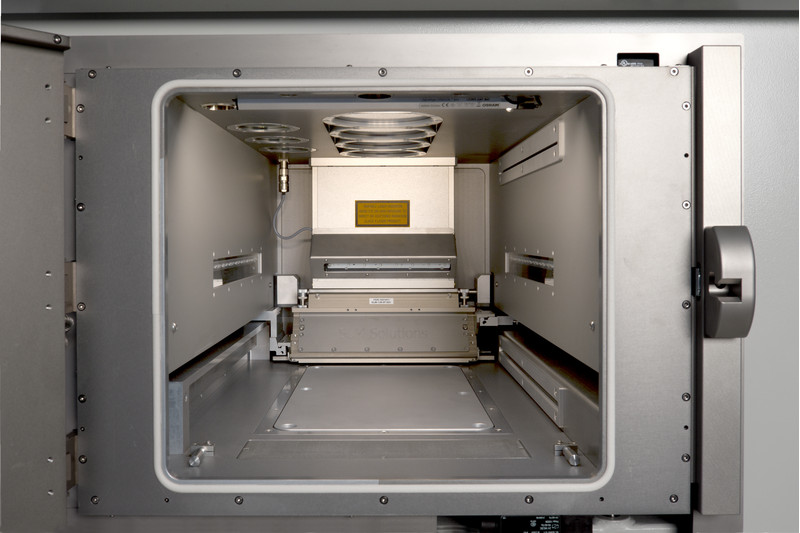

The Selective Laser Melting System SLM®500HL provides a build envelope of 500 x 280 x 365 mm³ and the patented multi-beam technology. In the high-performance SLM®500HL machine, four quad fiber lasers (4x 400 W) are in action simultaneously, increasing the build-up rate by up to 90% compared with the twin configuration (2x 400 W).

Your benefits

NUMBER OF LASERS

4

with invisible overlapping area

BUILD RATE

≥105cm3/h

TIMESAVING

50%

faster thanks to bidirectional recoating

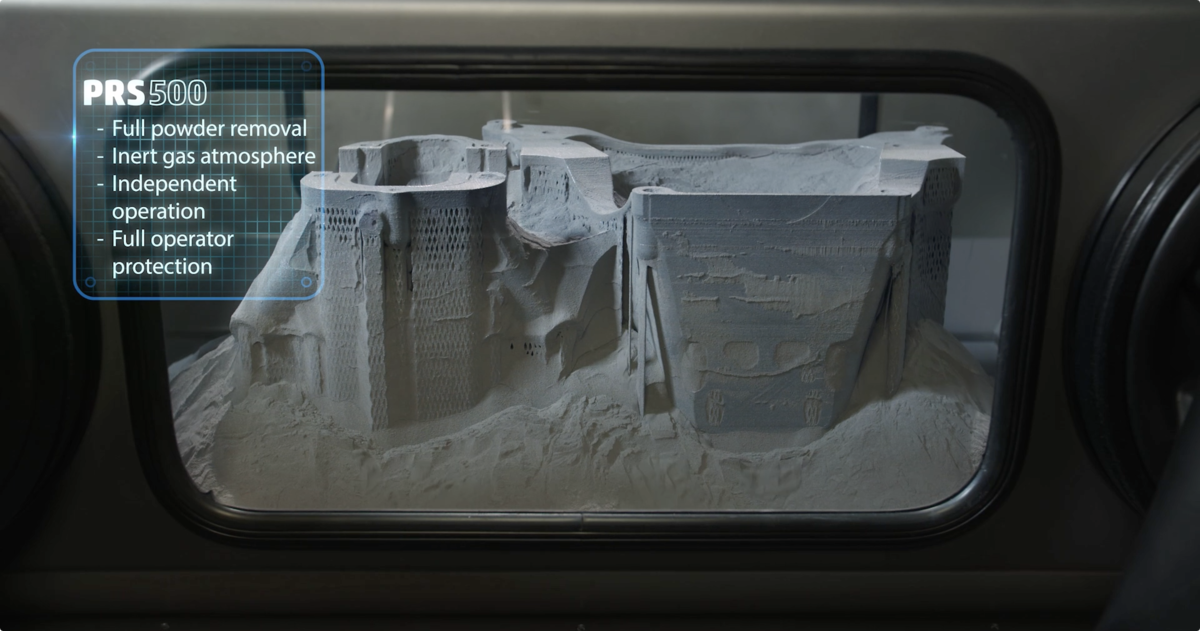

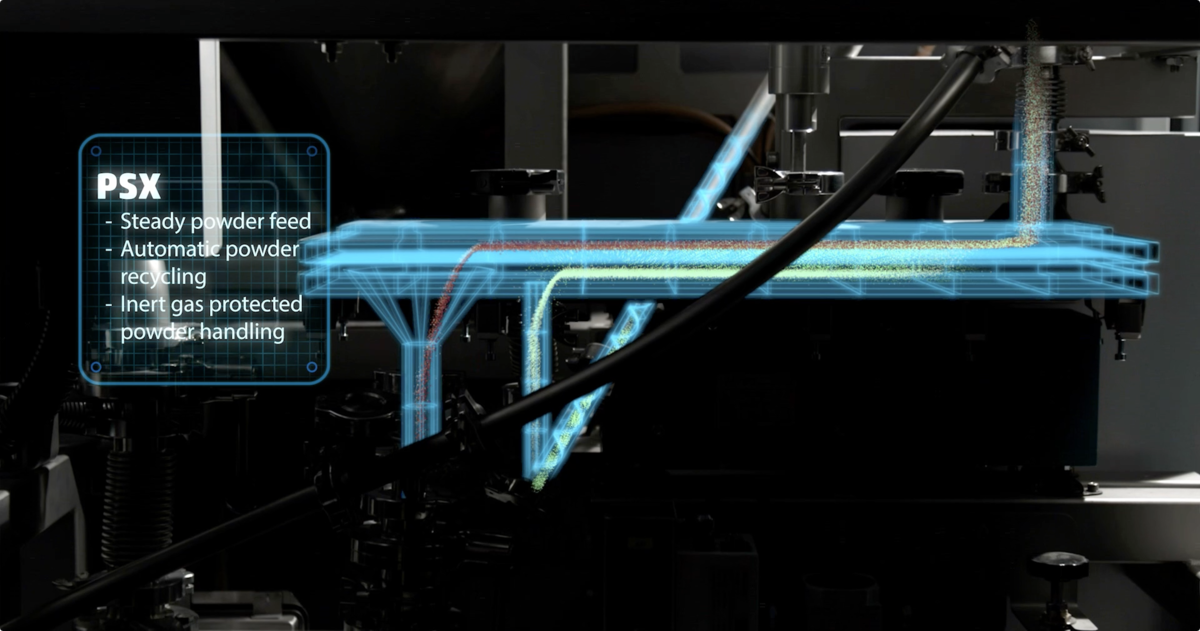

Closed loop powder transport, for your safety.

Transferrable Parameters : A Scalable Solution from SLM SOLUTION to grow with your needs.

Modify or develop completely new process parameters if necessary thanks to SLM’s Open concept.

SYSTEM PARAMETERS

Click to minimize or maximize

| System configuration for all types of metal powders* | |

| Build Envelope (L x W x H) | 500 x 280 x 365 mm³ reduced by substrate plate thickness |

| 3D Optics Configuration, Dual Configuration: with switching unit | Twin (2x 400 W), Quad (4x 400 W), Twin (2x 700 W), Quad (4x 700 W) IPG fiber laser |

| Build Rate | up to 105 cm³/h |

| Variable Layer Thickness | 20 µm - 75 µm |

| Min. Feature Size | 150 µm |

| Beam Focus Diameter | 80 - 115 µm |

| Max. Scan Speed | 10 m/s |

| Average Inert Gas Consumption in Process | 5 - 7 l/min (argon) |

| Average Inert Gas Consumption Purging | 70 l /min (argon) |

| E-Connection / Power Input | 400 Volt 3NPE, 64 A, 50/60 Hz, 8 - 10 kW |

| Compressed Air Requirement / Consumption | ISO 8573-1:2010 [1:4:1], 50 l/min @ 6 bar |

| Dimensions (L x W x H) | 5200 mm x 2800 mm x 2700 mm (inkl. PSX, PRS) |

| Weight (incl. / without powder) | approx. 3100 kg / 2400 kg |

*Subject to technical changes